Armoured cables are used to transfer electrical power or signals to different locations in a safe and reliable manner. These cables are designed to withstand harsh environments and provide protection against damage from external factors such as moisture, heat, chemicals, and physical impact. 4 core armoured cables are commonly used in industrial and commercial applications, and it is important to understand their current rating to ensure they are suitable for the intended use.

The current rating of 4 core armoured cable is the maximum amount of electrical current that can safely flow through the cable without causing overheating or damage. This rating is determined by various factors, such as the cable’s conductor size, insulation material, ambient temperature, and installation method. For 4 core armoured cable, the current rating is influenced by the cable’s cross-sectional area, conductor material, and insulation type.

The cross-sectional area of a cable’s conductor is the area of the circular metal wire inside the cable. The larger the cross-sectional area, the more current the cable can carry. This is because a larger conductor has less resistance to the flow of electrical current, which reduces the amount of heat generated. For a 4 core armoured cable, the conductor size is typically measured in square millimeters (mm2). The most common conductor sizes for 4 core armoured cables are 16 mm2, 25 mm2, 35 mm2, 50 mm2.

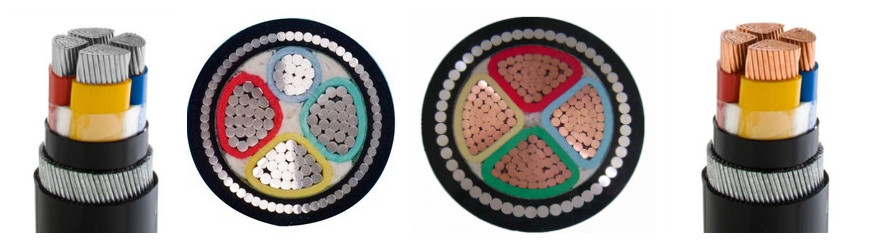

The conductor material also plays a role in determining the cable’s current rating. Copper is the most commonly used conductor material for armoured cables, as it has low resistance and high conductivity. However, aluminum conductors can also be used, as they are lighter and less expensive than copper. The current rating of aluminum conductors is lower than copper conductors of the same size, so a larger conductor size may be required to achieve the same current rating.

The insulation type of a cable affects its ability to dissipate heat generated by the flow of electrical current. The most common insulation materials for 4 core armoured cables are PVC (Polyvinyl Chloride), XLPE (Cross-linked Polyethylene), and EPR (Ethylene Propylene Rubber). EPR and XLPE insulation cable have higher temperature ratings than PVC, which means they can withstand higher operating temperatures without degrading. This allows for a higher current rating for cables with XLPE or EPR insulation compared to PVC insulation.

When selecting a 4 core armoured cable, it is important to consider the application’s requirements, such as the voltage, current, and ambient temperature. The cable’s current rating should be selected based on the maximum expected current load, which can be determined by calculating the power consumption of the connected devices. The cable’s installation method should also be considered, as factors such as cable length, cable tray size, and conduit type can affect the cable’s ability to dissipate heat.

The current rating of 4 core armoured cable formula:

Current rating = (cross-sectional area of conductor) x (conductor material factor) x (insulation temperature correction factor) x (installation method correction factor)

The conductor material factor is a constant value that accounts for the difference in resistance between copper and aluminum conductors. For copper conductors, the factor is 1. For aluminum conductors, the factor is 0.61.

The insulation temperature correction factor adjusts the current rating based on the insulation material’s temperature rating. For PVC insulation, the factor is 1. For XLPE and EPR insulation, the factors range from 0.92 to 0.72, depending on the maximum operating temperature of the cable.