Armoured cables and non-armoured cables are two types of electrical wiring used in a variety of applications. The primary difference between them is the presence of an armoured layer, which provides additional protection against mechanical damage and environmental hazards. While both types have benefits, understanding the differences between them can help you decide which type is best for your needs.

What Is Armoured Cable

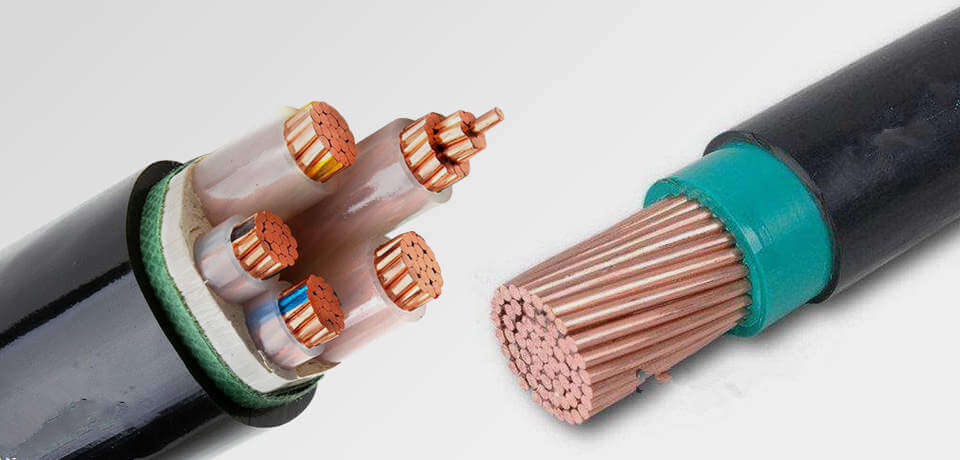

Armoured cable is a type of electrical wiring that has an additional protective layer of metal surrounding the internal wires. This layer can provide protection from physical damage, moisture and corrosion, as well as electromagnetic interference. The armoured layer is usually made from steel or aluminium, although other materials may be used for specific applications. This armoured layer is designed to protect the underlying cables from harsh external environments or conditions, such as vibration and movement, which can cause damage to the internal wires and create a hazardous situation.

The most common use for 3 core armoured cable is in industrial areas and commercial buildings where there are higher safety requirements, such as in places with high levels of dust or water. It is also commonly used in exposed areas where it may be subject to physical damage or vibration. Armoured cable is typically rated for higher voltages than non-armoured cable due to its increased protection against electrical shock.

The outer armouring on armoured cable comes in several forms including: interlocked aluminium armour (IAC), corrugated aluminium sheath (CAS) and galvanised steel wire braid (GSWB). IAC is one of the most popular types of armouring due to its low cost and flexibility. CAS provides superior protection but can be more expensive than other types of armouring due to its heavier weight and lack of flexibility. GSWB offers excellent protection but requires more labour when installing it due to its hard outer shell.

What Is non-armoured cable

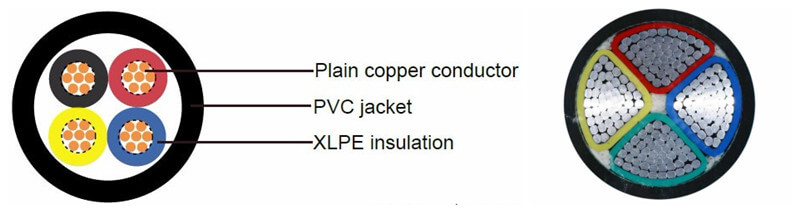

Non-armoured cable is a type of electrical wiring used to provide power and other signals in industrial and commercial buildings. It is typically composed of two or more insulated conductors which are protected by an outer sheath, such as polyvinyl chloride (PVC) or polyethylene (PE). Non-armoured cable is generally used for low voltage applications such as lighting and control systems.

The main difference between armoured cable and non-armoured cable is the presence of an armoured layer. Armoured cable consists of a metal covering that is usually made from steel or aluminium. This layer works to protect the wires from damage caused by moisture, abrasion, or rodents while also offering additional mechanical protection. This type of cable is commonly used in areas where there is an increased risk of environmental factors damaging the wires, such as underground installations or areas with high levels of moisture.

In comparison to non-armoured cables, armoured cables are more expensive as they require extra materials and labour during their installation. However, when exposed to extreme environments, armoured cables can offer superior electrical reliability over their non-armoured counterparts due to their extra layer of protection.

The difference between armoured cable and non-armoured cable

Armoured cable and non-armoured cable are both types of electrical wiring used in a variety of applications. The key difference between them is that armoured cable is covered with a protective sheath, while non-armoured cable does not have any form of protection.

4 core Armoured cable is typically made from metal or plastic, and it provides extra protection to the wires inside. This makes it suitable for use in hazardous environments where there is a risk of physical damage to the wiring. It also offers increased protection against water and moisture, as well as providing superior mechanical strength.

Non-armoured cable, on the other hand, does not have any form of external protection. This type of wiring is usually more lightweight and flexible than armoured cable, making it easier to install in tight spaces or around corners. However, without any form of external protection, non-armoured cables are more susceptible to damage from environmental factors such as moisture.

When choosing between armoured and non-armoured cables for your project, it’s important to consider the environment where the wiring will be installed and the specific requirements of your application. Armoured cables offer superior protection and durability in harsher environments, but may not be necessary for less demanding applications. Non-armoured cables offer greater flexibility but may need additional measures to protect them from moisture or physical damage if they are being installed in hazardous areas.

In conclusion, armoured cable and non-armoured cable are two different types of electrical wiring that are used for a variety of applications. The primary difference between the two is that armoured cable has an external layer of protective armouring in the form of metal strips or wires, while non-armoured cable does not have this external layer. This armouring can help to protect the wiring against physical damage, abrasion, and moisture. As such, it is important to understand the differences between these two types of cables before making a choice regarding which one to use for a particular application.