Micc Mineral insulated cable is manufactured from completely inorganic material. The copper sheath and conductors, insulated with magnesium oxide ensure that the cable is able to withstand the effects of fire and is fully usable afterward. The m.i. cable system provides a simple solution to many difficult wiring problems and makes for a dependable and permanent installation for virtually all types of electrical circuits. The copper cable sheath meets NEC grounding requirements. Suitable for 300 and 600-volt applications. Pressure tested to 2000 psi. Mineral insulated cable complies with Articles 330, 500, and 501 and all other applicable provisions of the National Electric Code.

To produce assemblies, the cable is cut to the desired length, pigtails brazed on and terminated with union-type glands with male NPT threads.

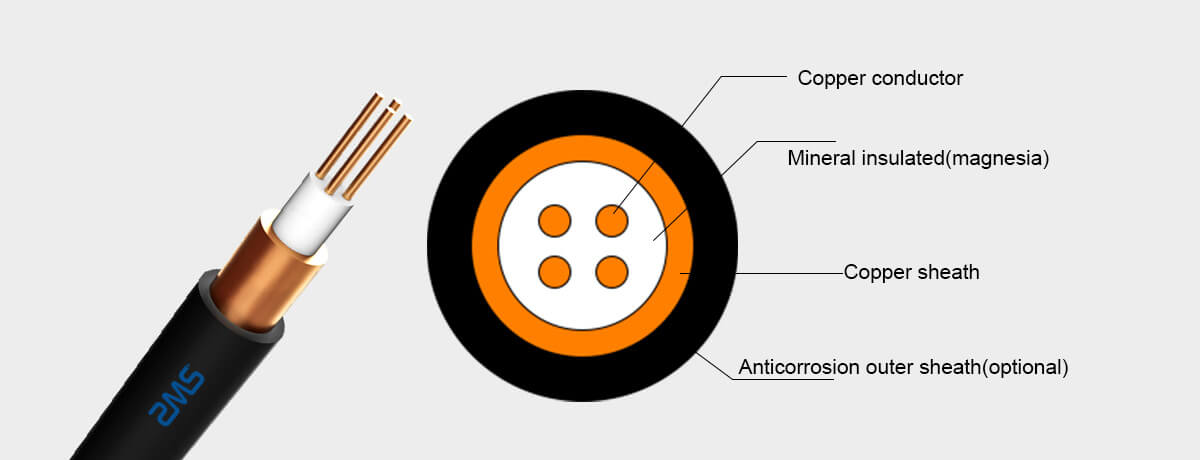

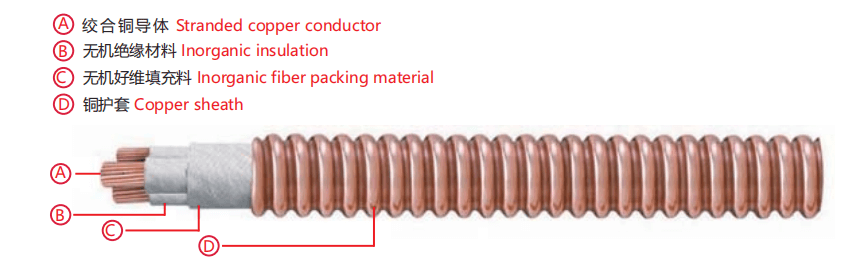

The structure of Micc Mineral insulated cable

1.Cable conductor: it is made up of stranded copper wires, with favorable flexural property.

2.Insulation layer: it adopts high-temperature resistant inorganic insulating materials

3.Copper sheath: copper materials, through special machining, with favorable flexural property, used as PE wire.

4.Outer sheath: it is made of plastic materials of low-smoke non-toxicity, with favorable corrosion protection.

MICC CABLE SPECIFICATION

| Type | Rated Voltage | Model | Name | Core | Section (mm2) |

|---|---|---|---|---|---|

| Lightweight | 500V | BTTQ | Lightweight copper core copper sheathed mineral insulated cable | 1 / 2 / 3 / 4 / 7 / 12 / 19 | 1.0~4.0 |

| WD-BTTYQ | Lightweight copper core copper sheath LSZH outer sheathed mineral insulated cable | ||||

| BTTVQ | lightweight copper core copper sheathed PVC outer sheathed mineral insulated cable | ||||

| Heavy-duty | 750V | BTTZ | Heavy-duty copper core copper sheathed mineral insulated cable | 1 | 1~400 |

| 03/04/2002 | 1~25 | ||||

| WD-BTTTZ | Heavy-duty copper core copper sheathed LSZH outer sheathed mineral insulated cable | 1 | 1~400 | ||

| 03/04/2002 | 1~25 | ||||

| BTTVZ | Heavy-duty copper core copper sjeathed PVC outer sheathed mineral insulated cable | 1 | 1~400 | ||

| 03/04/2002 | 1~25 |

The advantages of flexible micc mineral insulated cable fireproof cable

1.Excellent fireproof property, the fireproof rating not only satisfies the national standard GB12666.6 : categor y A 950℃ 90min, but also meet up with the U. K. standard BS6387-1994 : Class A 650℃3h; class B 750℃3h; class C 950℃ 3h; meanwhile, it also is able to withstand the water spraying or mechanical strike;

2.Long continuous length: the length can satisfy the length de-mand for power supply in spite of single-core or multi-core cable, and continuous length of each cable can be as long as 1,000m.

3.Large sectional area, sectional area of single-core cable reaches 630mm² and that of multi-core cable reaches 70mm²;

4.Property of flexibility, the cable can be wound on the cable reel, with the bending radius 6-10D, (D is the outer diameter of cable):

5.Smoke-free non-toxicity when burning, it adopts inorganic materials (non-inflammable mat e rials) for insulation, i ts burn-ing would not p roduce any harmful gas or secondar y pollu-tion, it is a environmental protection product;

6.High overload capacity, the cable not only is high in current carr ying capacity, but also has large overload capacity. Ac-cording to the wiring requirements, the surface temperature of cable usually is ≤70℃, i f i t will not be touched or will not contact with flammable building materials, the temperature of cable sheath can be heighten to 105℃. When coming across overload, long-term working temperature of fireproof cable can reach 250℃:

7.Proper ty of corrosion proof, organic insulated fireproof cable requires plastic tube or iron tube sometimes, the plastic tube is liable to deteriorate and i ron tube is apt to rust or erode, but the fireproof cable has copper sheath and the tube is need-less, besides, copper sheath has favorable corrosion resis-tance;

8.Free of electromagnetic inter fere nce, when wiring in the s ame ver ti-cal shaf t w ith information wire and control wire, because of shielding of copper sheath, the fireproof cable would not interfere the single and control wires or cables;

9.Favorable safeness, it is able to supply power and start the fire ex-tinguishing apparatus normally In flame, It reduces fire damage. Besides, it is reliable for personnel safety, as its copper sheath is a kind of good conductor, is the best ear thed PE wire, and covers the whole cable, The life of up to 100 years;

10.Long service life, high-temperature resistance and degradation-resistance of inorganic insulated material, its service life is many times of that of organic insulated cables, under normal working conditions, its service life can be as long as that of buildings;

11.Transportation and packaging of flexible fireproof cables includ-ing installatfon fittings are simple, nearly the same as that of general cables;

12.Favorable economical efficiency, due to advanced manufacturing processes and simple installation, overall cost of flexible fireproof cable is much lower than that of mineral insulated cable under the same conditions.

Main performance of micc mineral insulated cable

Fire-resistive performance

Never does the cable bum by itself, or does it cause the source of fire. Even in fire condition, it can still work normally. And,as long as the flame temperature is lower than the melting point of copper, the cable can be used continuously without change after the fire is removed. It would have better fire-resistive performance if the sheath and conductor material are changed,it can be used in oil gas environment.

Strong overload protection

When the circuit has the overload the plastic cable will come across the aging of insulation or breakdown for heat due to the over current or over voltage; while,MI cable has no loss only the heating temperature is not higher than the copper melting point. Even if the instantaneous breakdown occurs, the magnesia at the breakdown point still is magnesia after being melted at a high temperature. After the overload is removed, the cable has no change in performance.

High working temperature

Because the melting point of magnesia at the insulating layer is far higher than the melting point of copper, the max normal working temperature of bare cable can reach as high as 250

℃, and, it can work continuously under the copper melting point of 1,083℃ in a short time.

Waterproof, anti-corrosion, and explosion-proof properties

The cable adopts the seamless copper tube as the sheath, It is very compact among the conductor, insulation, and sheath, so, the cable not only has the function of resisting water, dampness, oil, chemical substance, etc., but also can prevent the spreading of combustible oil vapor, gas, and flame.

Excellent shielding property

The cable copper sheath is the best shield,it not only can prevent other cables from being interfered with by this cable but also can prevent this cable from being by an external electromagnetic field.

Strong radiation resistance

As the material of cable is inorganic, the electric and mechanical performance of cable can not be changed after suffering from nuclear radiation.

Long service life

The cable is made of inorganic material, therefore, it is not aged, and its service life reaches hundreds of years at least.

Small outer diameter and lightweight

Compared with the plastic cable of the same current-carrying capacity, the outer diameter of the MI cable and the weight of that is reduced much, in terms of these, the cable can reduce the occupied space and is easily installed.

Please leave your inquiry message, we will send you price asap!